Applications

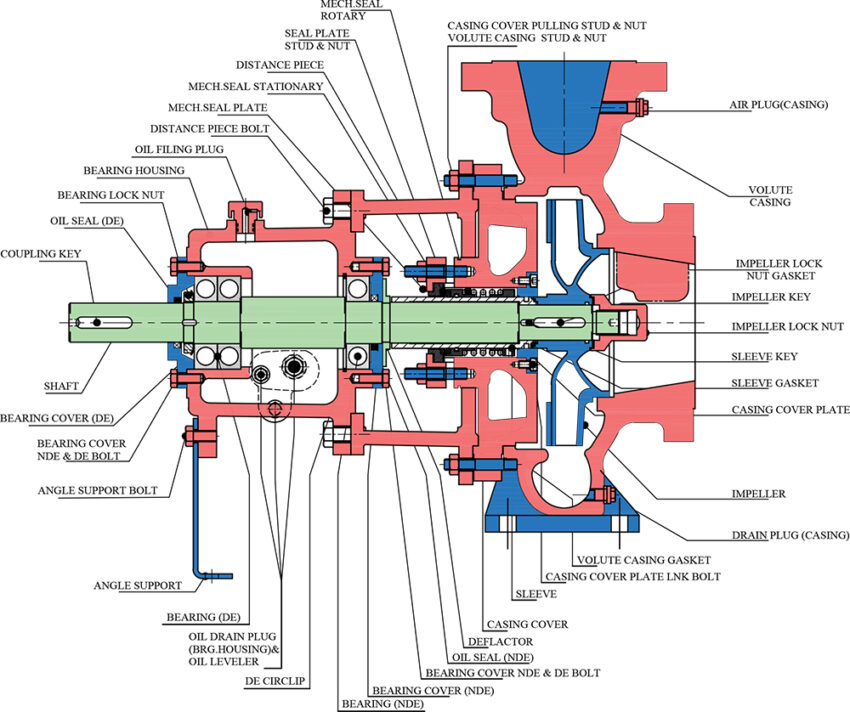

Volute Casing

This particular pump is made with one piece self-venting volute casing which has top suction and top centerline delivery branch. With the pump feet integrally cast into the volute casing, the bottom feet of the machine transfers residual pipe stress by the shortest possible route to the base plate and foundation.

Bearing Frame

Just three are necessary to cover an entire range. All pumps belonging to a bearing frame have an identical shaft, bearings, shaft sleeves, and impeller fastenings. In addition to the standard sight glass, every bearing frame can be equipped with a constant level oiler. For pumping temperature more than 180͒C or 160͒C in a steam-jacketed pump, a lubricating oil cooling circuit can be fitted in the oil pumps of bearing frames.

Shaft Sealing

Supplied with either packing or mechanical seals in a stuffing box with connection for sealing and flushing liquid. Simple change over from the packaging to a mechanical seal is possible with the aid of various makes, unbalanced as well as balanced ones can be easily fitted in the standard stuffing box.

Shaft & Bearings

The shafts attached to this machine provide effortless performance, owing to the oil-lubricated angular contact and cylindrical roller bearings. All the bearings on this machine are perfectly aligned and exhibit minimum deflection. The shaft is made with a fully enclosed PTFE Gasket, embedded between the impeller nut-shaft and shaft sleeve, which protects the liquid being transported.

Impeller

To fulfill your low NPSH requirements, the machine is made with closed and semi-open impellers specially designed for this purpose. Its back vanes help to keep the machine hydraulically balanced. Furthermore, the machine is also very convenient is fixing impellers on the shaft with the help of impeller nuts.

M.O.C.

C.I., C.S., SS 304 / 304 L, SS 316/ 319 L, Bronze, Alloy-20, CD4MCU, Hast Alloy B/C etc…

Features

Modular Constructions Along With High Interchangeability

Versatile Shaft Sealing Arrangement

Glands Packaging As A Standard Arrangement With Option Of Mechanical Seal

Design That Results In Minimum Downtime

Back Pull Out Design Enabling Easier Removal For Inspection & Maintenance

Closed Impellers That Preserve Efficiency For A Long Time

Three Bearing Design Options Which Result In Higher Productivity

Bigger Shaft And Bearing Size Enabling Sturdy Design

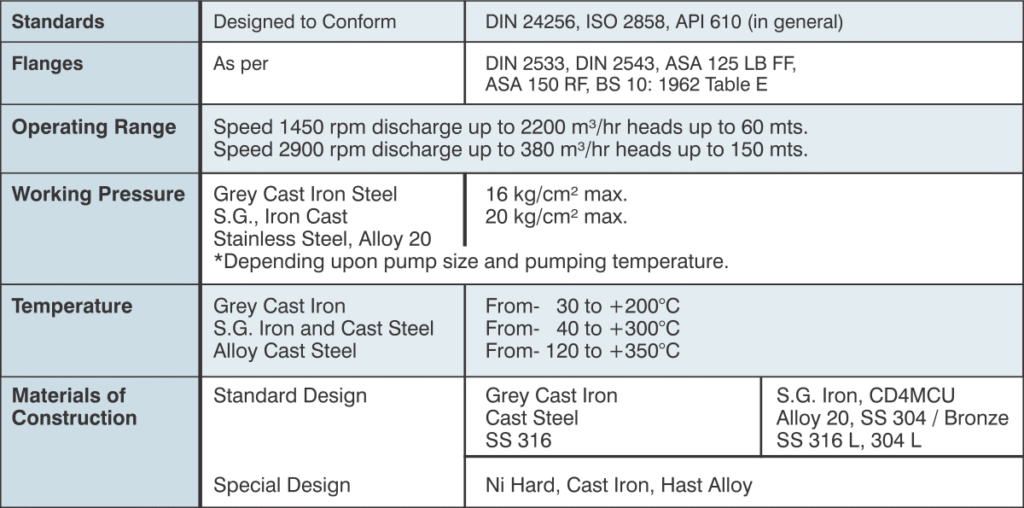

Material Specifications