Design

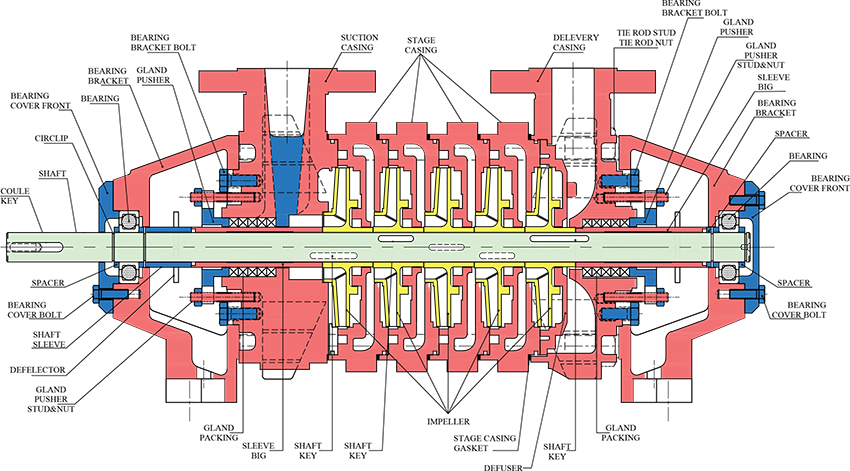

The pump design is multistage construction with verticle split casing & intermediates, allowing for high head discharge. It is a horizontal pump with a stage tie attached with suction & discharge brackets through rods. The pump base is cast integral with suction and discharge brackets.

Bearing

Heavy-duty ball bearings that are capable of carrying thrust load in either direction are used in pump design. In addition, grease-lubricated bearings are used, which ensure a longer life for the pumps.

Flanges

All the flanges are faced and drilled as per DIN standards.

Impeller

Impeller has axial thrust balancing and is die-casting with a very smooth finish to provide the highest efficiency level. In addition, impellers can be made out of any material depending on the customer’s process requirement.

Stuffing Box

Un-cooled soft-packing are provided with a sealing connection on the suction side of the pump. For higher pumped media temperatures, a stuffing box can be provided with a cooling cover which facilitates external cooling.

Drive

The pump is designed to drive by an electric motor through flexible coupling. The direction of rotations is perceived as clockwise when viewed from the driver’s end. As a result, suction is nearer to coupling and discharge at the other end.

Features

Designed For High-Pressure Industrial Applications

It Comes With The Option Of Cooling Cover Stuffing Box

Robust Pump Construction For Stable Operations Even At High Pressure

Can Handle Water And Liquids At High Temperature

Impeller Material Can Be Varied To Suit Customer Applications

Proves To Be Very Economical And Efficient For High-Pressure Applications

Material Specifications