Centrifugal Pump Rebuild Services

Centrifugal Pump Rebuild (before)

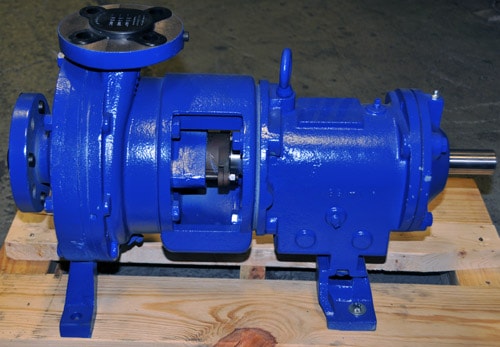

Centrifugal Pump Rebuild (after)

Cassandra Pumps Inc prides itself on our almost one hundred and forty year history in the pump business. Our longevity within the industry proves our continuous commitment to product, service, and customer relations.

When a new pump leaves our facility, it goes with the assurance to the customer and end user that as an Original Equipment Manufacturer (OEM), we pledge to provide ongoing after market support to maintain the relationship created. In addition to our warehouse of stocked parts and in house machining facilities for drop-in parts orders, Cassandra Pumps also provides comprehensive rebuild services of all models from our product line. That being said, while our main focus is obviously our own pump line, we also have proven capabilities of repairing and refurbishing non Cassandra Pumps products.

Benefits of continuing to utilize our services include the absolute assurance that with every parts replacement order or rebuild repair / upgrade, the pump will consistently have OEM parts of exact form, fit, and function for the best suitability of the environment or application it was initially designed for. Maintaining original bills of material is an act that we meticulously follow to ensure any modifications made over the lifetime of the pump are properly recorded to indicate the why, when, and how of such amendments.

Turnaround times of completion of parts orders, rebuilds, and refurbishments all come with rush expediting options and each order is closely monitored to ensure that any breakdowns are minimized or ideally, avoided altogether. Should the need exist; emergency field repair can also be coordinated with our on-call technical service department.

Cassandra Pumps stands behind all products and services we offer through our solid warranty guarantees on labour, parts, and materials. We firmly believe in servicing what we sell and also work to provide necessary engineering and technical support as customer and end user needs arise.

Centrifugal Pump Refurbishment Capabilities

| General Capabilities | Emergency Field Repair Installation Product Procurement |

| Refurbishment Capabilities | Dynamic & Static Balancing CNC Machining Milling Bore Milling Turning Overhaul / Repair Seal Replacement Hydrostatic Testing Customer Specified Testing Material Upgrades |

| Pump Types Repaired | Centrifugal Open Impeller End Suction Double Suction Multistage Pumps Non-Clog Open Impeller Refuse Pumps Vertical Cantilever Vertical Sump |

| Run Dry | We are Capable of Designing Pumps to Run Dry if Specified |

| Use With Solids | Yes |

| Construction Material | Casted Alloys Bronze Nickel Bronze Tin Bronze Cast Iron Ductile Iron Duplex / Super-Duplex Hastelloy 316 Stainless Steel Cast Steels Titanium Any other workable Material |

| Turn Around Times | Rush Services Available Emergency Services Available |

| Industry Standards | ANSI American National Standards Institute ASME B31.1 CSA Standards Z299.3 / Z299.4 IEEE841 ASME B73.1 ISO International Organization for Standardization ISO 9001:2008 Hydraulic Institute ASME American Society of Mechanical Engineers |

| Industry Focus | Industrial Applications Oil, Gas, Petroleum Chemical Processing General Industries Power Generation Sewage / Waste Water Mining |

| Intended Applications | Coal/Tar Heating & Cooling Circulation Multistage High Pressure Boilers Sewage Solids Heavy Duty, Tough Applications |